Midasia Label Printing and Packaging

Fashion is nothing but consequences of Choice

Midasia Label Printing

Midasia Group started label printing apparels from 20XX. Over the years we have developed as a team with expertise in enjoying the art of screen printing. Doing screen printing is not a work, but that’s the happiest part for us. Equipped with best in the industry machines and high-quality inks, we print no less than the best which can be worn till fabric is torn. More than anything, we believe in the systems and process put in place to handle many small productions hassle free.

Process of Label Printing:

- Clients give us the designs and order details either by designing from our design tool or submitting the order form. Clients will get a confirmation email or a call asking for missing part of information.

- Our design team investigate each design file of the order, separates colours and creates a separate screen for each colour. We do minor design corrections and enhancements for the print to look great on the apparel and the design gets your approval before transferring it to the production team.

- The production process starts from inking the screen with appropriately approved colour shades and the screens are lined up for printing.

- The printed and cured shirts & pants are sent for heat fusing with a high-temperature setting. This ensures the print merges well with the fabric and gives a soft hand feel.

- The clothes move on to the inspection team. They are our guardian angels, they protect our brand name with rigorous checking and reprinting for any small mistakes.

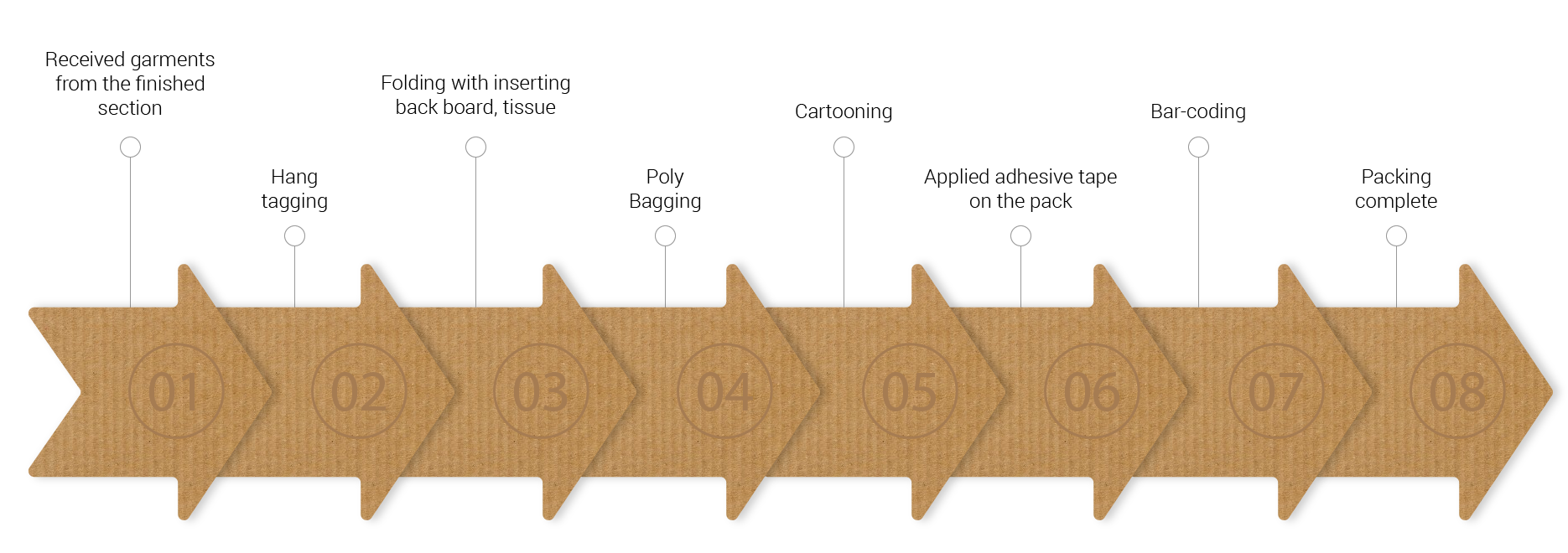

Midasia Packaging

Garments packaging is the process of wrapping, compressing, filling or creating of goods for the purpose of safety or security and their appropriate handling. This is the ultimate process in the production of garments, which prepares the completed merchandise for delivery to the clients. It is an important part of the garment manufacturing process. Garments packaging is also use to get lot of attention from the clients. These processes come under the materials management methods and are no less important than other systems used in the factory. After completing the entire manufacturing task, apparel is required to be packed. After packing, it is placed in cartons as per instructions and then it is stored in a store section before it is delivered to the respective buyer or clients.

Objectives:

- Preventing any damage to the product during transportation

- Enhancing the features of the products and goods to the consumer for a sale of it

Flowchart of Packaging